3D printing has been getting a lot of buzz recently, its evangelists have been cranking up the rhetoric with some pretty heady predictions of a brave new world of home fabrication of, well, pretty much anything. Even some more mainstream publications such as The Atlantic have got in on the act. I’ve been reading all this with a bit of skepticism, as a great deal of the excitement is based on what could charitably be called an incomplete understanding of the manufacturing process and materials engineering.

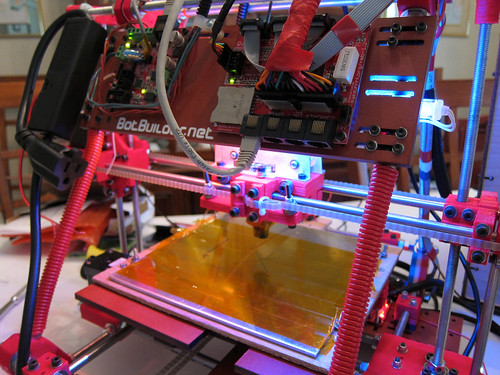

3D printers that have created all this excitement are open source, and amazingly affordable, typified by the Makerbot and RepRap, to name a couple of the more popular ones. They print in a way not dissimilar from 2D ink-jet printers, but instead of laying down ink, the printhead deposits a layer of physical material, generally a plastic. It does this over and over, moving in tiny increments on the z axis to build up a 3D shape. The file describing the object divides it into tiny horizontal slices, each slice one increment on the Z axis, its height determined by the printer’s resolution.

These machines are meant for home/personal use by members of the maker community. I think it’s fair to say that they have somewhat limited capabilities in terms of size, materials and resolution. They’re best suited for creating objects that fall into the “lump of plastic” category. Resolution is so-so, and striations are clearly visible as the layers are built. But these are essentially hobbyist machines, and for their low cost, they have astonishing capabilities.

But it’s a long way from the capabilities of these 3D printers to the idea of a single machine that can create any and all products that we use on demand and in our homes. A recent blog post by Christopher Mims at the MIT Technology Review ruffled quite a few feathers:

the notion that 3-D printing will on any reasonable time scale become a “mature” technology that can reproduce all the goods on which we rely is to engage in a complete denial of the complexities of modern manufacturing, and, more to the point, the challenges of working with matter.

The thing to bear in mind here is that Mims is speaking of “all the goods”, and that includes incredibly complex cellphones as well simple things like plastic egg cups. I believe that he is open to the possibility of “some of the goods” being produced via 3D printing, and I think that’s the camp I’m in for now. There was an interesting reaction post to Mims’ piece by Tim Maly, again in the MIT Technology Review, arguing that the trajectory of 3D printing may be a similar one to 2D printing. He envisions a future where current cost structures get turned on their head:

Something interesting happens when the cost of tooling-up falls. There comes a point where your production runs are small enough that the economies of scale that justify container ships from China stop working. There comes a point where making new things isn’t a capital investment but simply a marginal one. Fab shops are already popping up, just like print shops did.

As the cost of energy continues to increase, it’s a seductive argument. Moving production closer to consumption is likely to become a greater imperative in years to come. Maly makes the distinction between desktop-class printers and commercial scale 3D printers, and it’s well to bear that in mind. The capabilities of today’s Makerbot are certainly only the tip of the iceberg of what 3D printers are already capable of. I think where the evangelists miss the mark is in assuming that all this will happen in your home. A lot nearer your home probably, but not in it, I think.

I’ll take a swing at predicting what we will and will not be 3D printing, and where, in a future post. In the meantime, I’d be very curious to hear your take on what we can expect to see from 3D printing in the future.

Image: Flickr user Jabella

Like this? More from the technology category.

Follow me on Twitter (@intudes) for interesting links and occasional observations.

Subscribe to the RSS feed, and don’t miss another post.

Pingback: The Future of 3D Printing