The Toaster Project

A Toaster made completely from scratch. Thomas Twaites’ quest to build a toaster is a strange and wonderful tale of one man’s obsession. Not content with buying the materials and assembling a toaster of his own design, he did the maker movement one better by actually mining his own copper, iron, nickel and mica. He went to great lengths to refine the materials, no small trick at a domestic scale.

…my first attempt to extract metal involved a chimney pot, some hair-dryers, a leaf blower, and a methodology from the 15th century – this is about the level of technology we can manage when we’re acting alone. I failed to get pure enough iron in this way, though if I’d tried a few more times and refined my technique and knowledge of the process I probably would’ve managed in the end. Instead I found a 2001 patent about industrial smelting of Iron ores using microwave energy.

Along the way he’s made some interesting observations about the provenance of our everyday products, something few give much thought to. Most of us are blissfully unaware of the range and scale of activities that go into the manufacturing of a product even as mundane as a toaster. To paraphrase my university design prof Wim Gilles: “Most people think their toasters were dug out of a mountain just behind the Sears store.”

Thomas Twaites’ quest has been documented in his book The Toaster Project, published by the Princeton Architectural Press. It’s been getting great reviews – I’m putting it on my list.

via: www.jameco.com

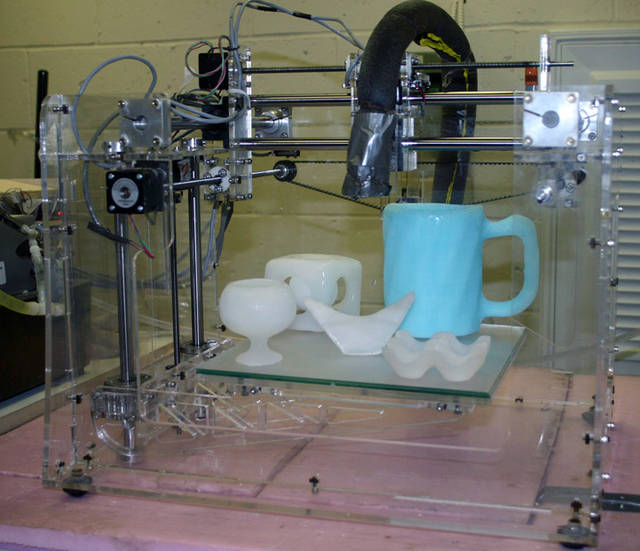

3D Ice Printing

There are lots of stories about 3D printing these days, but the idea of using ice as a print medium was new to me. The Iceman Printeth is a brief account of a research project from Pieter Sijpkes, a professor emeritus at McGill University. It seems almost inevitable that this project originated at McGill in Montreal, a place that knows all about cold and ice.

Although ice as a medium has limited practical applications, it’s rather intriguing as a low-cost, disposable material for visualizing forms. I’m tempted to add environmentally friendly to the list of adjectives, but with the energy required for cooling, that’s probably not entirely accurate.

According to the project website, there are plans to create a bridging technology that would transfer forms from ice to a more durable material.

Presently, casting techniques are being investigated in order to produce high-quality metal copies from ice originals.

It appears that the 3D printing service provider Shapeways has developed a similar process aimed at reproducing sculptural forms in ice.

________________________________________

Like this? More from the industrial design category.

Follow me on Twitter (@intudes) for interesting links and occasional observations.

Subscribe to the RSS feed, and don’t miss another post.